The Future of Rapid Prototype and Manufacturing

Rapid prototype and manufacturing are crucial components in the modern industrial landscape, particularly within the realm of metal fabrication. These methodologies not only streamline production processes but also enable businesses to innovate swiftly while reducing costs and waste. In this comprehensive article, we will explore the multifaceted aspects of rapid prototyping and manufacturing, its significance in various industries, and how it shapes the future of metal fabrication.

Understanding Rapid Prototyping

At its core, rapid prototyping refers to the quick fabrication of a scale model or assembly using three-dimensional computer-aided design (CAD) data. This process is invaluable for testing and validating designs before moving to full-scale production. With the growing demand for customized products and shorter product life cycles, rapid prototyping has become a game-changer in manufacturing practices.

Key Advantages of Rapid Prototyping

- Speed: The foremost benefit of rapid prototyping is its ability to produce models swiftly, significantly cutting down development time.

- Cost-Effectiveness: By identifying design flaws early, businesses can save money on material and labor costs associated with traditional prototyping methods.

- Design Flexibility: Rapid prototyping allows for adjustments in real-time, fostering an innovative approach to product development.

- Risk Reduction: Early testing of prototypes minimizes the risk of costly errors in the final product.

The Role of Manufacturing in Prototyping

Following the rapid prototyping stage, manufacturing takes the reigns to transform those prototypes into tangible products. This phase is equally critical as it requires precision to ensure the end product meets the required specifications and quality standards.

Manufacturing Techniques in Metal Fabrication

In the context of metal fabrication, several techniques play a pivotal role in the manufacturing process:

- CNC Machining: Computer Numerical Control (CNC) machining enables the fabrication of high-precision parts through automated cutting and shaping processes.

- Laser Cutting: This technique provides excellent accuracy and speed for cutting metal sheets and shapes, making it a preferred choice for custom design work.

- Metal Forming: Techniques such as bending and rolling are utilized to shape metals into desired forms efficiently and effectively.

- Welding: Welding processes are essential for joining metal parts together, ensuring structural integrity in assembled products.

Applications of Rapid Prototyping and Manufacturing

The implications of rapid prototype and manufacturing are vast, touching various sectors:

Aerospace and Defense

The aerospace industry often relies on rapid prototyping to reduce the time required for design iterations. Components such as brackets, fittings, and other structural elements benefit from rapid manufacturing, which allows for faster deployments and enhanced safety protocols.

Automotive Industry

Within the automotive sector, rapid prototyping is used to create both exterior and interior parts. The ability to test new designs quickly can mean a significant competitive advantage in a fast-paced industry. Additionally, manufacturing processes such as 3D printing are increasingly being used to produce tailored components.

Consumer Electronics

Consumer electronics require rapid adaptation to innovations and shifts in consumer preferences. Prototyping and manufacturing provide opportunities for businesses to create iterations of products such as smartphones and wearables with faster time-to-market. This ensures they stay ahead of market trends.

The Future of Rapid Prototype and Manufacturing Technologies

As technology progresses, we are witnessing a myriad of advancements in rapid prototype and manufacturing processes. These innovations promise to revolutionize the way industries operate:

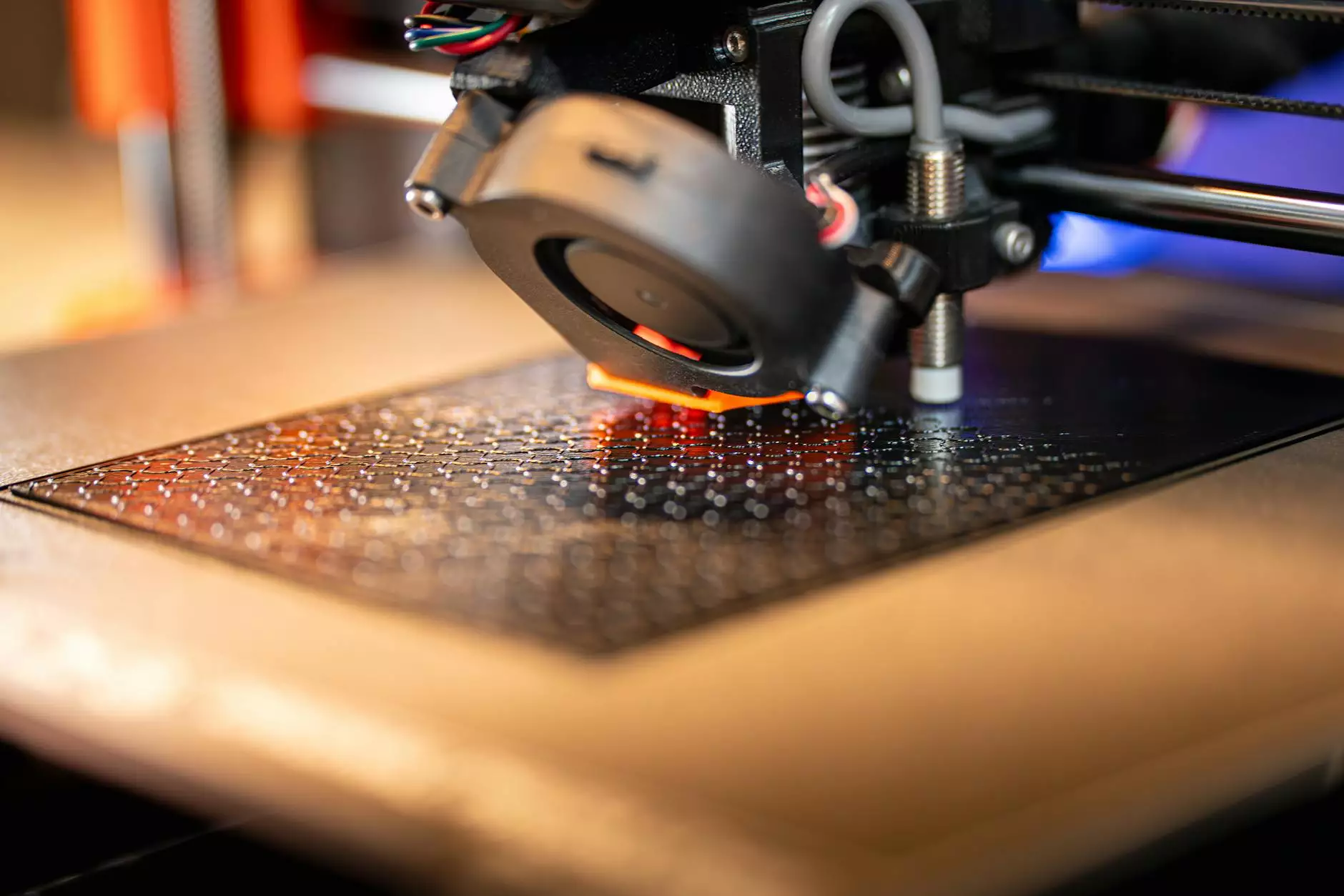

3D Printing

3D printing is arguably the most impactful development in rapid prototyping. Its versatility allows for the production of complex geometries that would be impossible with traditional methods. Materials used in 3D printing are also evolving, encompassing metals, plastics, and even bio-materials.

AI & Machine Learning

The integration of artificial intelligence (AI) and machine learning into manufacturing processes enhances productivity and efficiency. Predictive analytics helps in optimizing production schedules, while machine learning algorithms can improve the precision and quality of prototypes.

Automation

Automation continues to shape manufacturing, reducing labor costs and increasing consistency in product quality. Robotic process automation (RPA) combined with rapid manufacturing techniques allows businesses to maintain flexibility while scaling production effectively.

Challenges in Implementing Rapid Prototyping and Manufacturing

While the benefits are substantial, businesses face challenges when implementing rapid prototyping and manufacturing techniques. Some of the most notable include:

- Initial Investment: The upfront cost of advanced prototyping equipment can be a barrier for small and medium enterprises.

- Skilled Labor: There is a growing need for skilled professionals who can operate advanced manufacturing technologies.

- Material Limitations: Not all materials are suitable for rapid prototyping, which may limit design possibilities.

Conclusion

In conclusion, the realm of rapid prototype and manufacturing is at the forefront of the metal fabrication industry, fostering innovation while addressing the increasing demands of modern markets. As technology advances, industries that embrace these practices will likely lead their sectors, driving efficiency and improving product quality. With the right approach and resources, businesses can leverage these methodologies to navigate the complexities of today's production challenges and thrive in a competitive marketplace.

Why Choose DeepMould for Your Metal Fabrication Needs?

At DeepMould, we specialize in delivering high-quality metal fabrication services that incorporate the latest in rapid prototyping and manufacturing technologies. Our commitment to excellence and innovation ensures that we provide unparalleled service to our clients, making us a leading choice in the industry. Explore our comprehensive offerings and discover how we can help bring your ideas to life.

For more insights into rapid prototyping and manufacturing, contact DeepMould today!